The First Mile — “An Insider’s Story of How to Move a House”

My name is Jeff McCord, and I am a Committee Member for the “Save the Stone Cottage” project. I often tell people that—in 2007—I “ran off and joined the circus!”

It had all started when, in 2001, I had moved a house from California Ave SW to SW Graham St in West Seattle, saving it from the path of demolition. I didn’t realize it at the time but—by rescuing that beautiful Craftsman-style home—I was getting a crash course in “house rescue” which would lead me to an abrupt career change. That experience taught me about the unusual process of how a house gets moved.

I ran off and joined the circus!

Jeff McCord

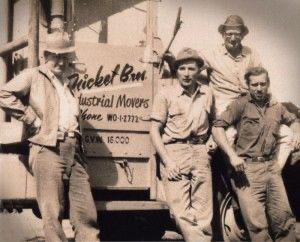

Subsequent to moving my first house, in 2007 I met up with Jeremy Nickel, one of the family members representing Nickel Bros, a family-owned house moving company founded Port Coquitlam, BC in 1956.

I joined Nickel Bros, ultimately helping to set up the US office (near Everett, WA) and serving in various capacities over the years; including marketing, PR, government relations, estimating, and “House Rescue” as moved-house salesperson. During my tenure, I helped save over 100 houses that would have otherwise been demolished—typically to make way for new construction.

Why do I say I “joined the circus?”

I quickly realized that Nickel Bros is to house moving like the ‘Flying Wallendas’ are to the circus trapeze.

The Nickel Bros are a family of self-taught, life-long experts at the highly complex, technical, and potentially dangerous art of preparing, supporting, lifting, and moving houses of all shapes and sizes. Typically a house moving families pass down their knowledge and invented techniques from their fathers and uncles to their sons, nephews, daughters, and nieces over many, many decades. Their understanding of real-world structural engineering is unmatched.

The Nickel Bros have moved everything from small Craftsman Bungalows to 200-ton brick mansions!

Like a circus family, they tend to be somewhat nomadic, traveling to all corners of the country or region where they ‘perform’ their art.

During my ten years with Nickel Bros, I too had to learn by doing. Since Nickel Bros moves or lifts up to about 300 houses per year, each job is unique, complex, and challenging. As the careful and exhaustive preparation and permitting is being done, creative problem-solving often has to occur on the fly. Like the Wallendas, safety and discipline is key. A house move is conducted with military-like precision, each crew member assigned to a task; each assigned to a corner of the house during a move, and each watching each other’s back. With all of the complex work that goes into bringing a house move to fruition, it is very much a ‘high-wire act’ to save each and every house!

It is very much a high-wire act to save each and every house.

Jeff McCord

Here’s How We Roll: Step-by-Step Process to Move a House

Stabilize the base with a ‘ledger board’ to support underneath and hold in place under the stone façade, and use vertical boards as ‘strapping’ to secure the exterior stone façade.

Provide interior support with cross-bracing and plywood for shear strength.

Crews dig down at key locations under the first floor walls to create trenches at both front and side beam locations. This allows the two layers of long metal I-beams to be pushed into place.

First, crew members push the metal cross beams under the floor from the side of the house to create the top layer of support.

Next, crews install the main beams in two locations from the front of the building under the cross beams to the back of the building. They are rolled into place using heavy rollers—either by hand or with the crane truck or an excavator. Once installed, these beams (along with the upper layer of cross-beams) will support the entire length of the house.

Note: The main beams are typically set in about five to seven feet from the outside walls of the house. These locations are planned based on the width of the house to account for a “cantilevering” effect. This effect helps to balance as the house is maneuvered during the move.

Closer to move-day, the cribbing consisting of four-foot-long wooden blocks is loaded under the house and hand-stacked in a Lincoln-Log pattern in four locations under the main beams.

The crew loads in the heavy hydraulic jacks—which are cylinders, or ‘rams,’ topped by a circular metal plate. These heavy jacks (approx. 100 lbs. each) will make contact with the two main beams during the lifting process. These jacks are placed on timber supports within each of the four cribbing piles to prepare for lifting.

Using a “balanced jacking system,” workers activate the jacks with a master valve to lift up the building—level and evenly balanced—about 18-inches at a time.

With each lift, the crewmembers continue to build up the gap with more cribbing, resetting at a higher level for each ‘throw’ or relocation of the jacks.

Once the building is lifted high enough to move in the dolly wheels, the crew installs ‘bridging’, which is a platform of beams under the house. The bridging is so that dolly wheels can be moved into place and installed to roll the house out of the site.

Note: The two rear dollies are installed below the parallel main beams to support the rear of the house for the move. Each dolly has eight wheels and looks somewhat like airplane wheels. They can be raised and lowered, as well as each axel able to be turned using a hydraulic system.

Once the rear dollies are in place, the two rear cribbing piles can be removed.

The main beams protrude about five to seven feet out of the front of the house. At this point, a front cross-beam called a ‘bunk’ is installed below the protruding main beams. The bunk has a connector (referred to as a ‘third wheel’) that will later allow the ‘tractor’ (truck head) to be hooked up to the house for towing.

On move day, the tractor is driven to the site and carefully positioned into place to prepare for the move. Leading up to midnight on Friday night (when the house is allowed by SDOT permit to be on the road), the tractor is backed toward the bunk until it locks into place in the third wheel. Chains and other securing methods are then installed as a ‘safety’ before the house is driven off the site.

The remaining hydraulics are connected to the front controls on the tractor, thereby allowing the dollies and third wheel to be controlled by the driver and other operators during the move.

At the stroke of midnight, the tractor engine is revved up for the move, and the house is slowly pulled off of the site and onto the right-of-way for its journey down the road. Moves typically take about four to six hours — especially if there are overhead utilities that have to be lifted over the house or onto the street for the house to cross over. However, in the case of the Stone Cottage, this move may go much more quickly (likely an hour or less). The house will travel at about walking speed, but could go faster if needed.

Note: During some more complex moves, it is actually possible to tip the building as much as 15° to get over bridge railings, mailboxes, and other obstacles along the route (though that won’t be needed in this case). Also, the rear dollies (axels) can be turned in the opposite direction from the tractor—much like an articulating firetruck—in order to navigate complex intersections and tight turns. Also, a back-and-forth approach can be used to go around tight intersections, traffic light arms, and other obstacles.

Once the procession reaches its destination and the house is maneuvered into place (in this case for storage), the crew locks down all of the equipment and leaves the site for some much-needed rest (and a hearty breakfast). Typically, the house movers come back a day or two later to remove the tractor, dolly equipment, and bunk, and go through a ‘reverse’ process to lift and place cribbing in four locations under the main beams like before, using the hydraulic jacks to lower the house onto the cribbing like before.

Note: Houses can be securely stored indefinitely once they are placed into storage. In many cases (if they are at their final destination), they are left on cribbing while foundation forms are built directly below the outside rim of the house. In fact, the house can act as a ‘template’ for the foundation by dropping plumb lines to the foundation corners, allowing for a perfect fit (even if the house is not perfectly ‘square’). Once the forms are built, inspected, and approved, the concrete is poured, and the house can be lowered onto the new foundation within about 7 to 10 days, and bolted down securely for another 100-years of life!

Interesting Fact: In the case of the Stone Cottage, Nickel Bros plans to shrink-wrap the house to protect it from the elements while it is being stored!

Here are a few other interesting facts about house moves:

- The fact that the building is usually supported by two rear dollies and the ‘third wheel’ and tractor in the front means that it is a triangular shape rather than a square. This is important because a triangle allows the house not to be torqued like it might be by a four-point system as it goes over uneven terrain, etc.

- Because the Stone Cottage has an inner layer of traditional stud wall construction, it is actually very resilient to the movement forces along a move route. The stone façade is merely applied to the wood frame walls and is well-supported by the ledger boards and strapping during the house move.

- Houses with interior plaster walls and exterior stone or masonry work typically do very well in a move and any cracking that may occur is typically minor and considered ‘cosmetic’ in nature. Often, any cracking is a result of existing stresses that have occurred over decades as the house has settled, perhaps opening up slightly as it is lifted and/or moved.